Call us Today

Comec RP1000CNC Head and block resurfacer

The RP 1000 CNC is a resurfacing machine for cylinder heads and engine blocks of cars and trucks as well as for all flat surfaces which require a maximum accuracy of the contact surfaces.

Comec RP1000CNC resurfacer

All machine parts, like the base, the table, the column and the head are made of widely ribbed cast iron of the best quality, thereby offering highly rigid and sturdy features.

The table feed is operated through a recirculating-ball screw that is extremely precise even at slow feed speeds. A frequency inverter controlling the screw is attached to the motoreducer to offer different speed feed that can be widely adjusted with a potentiometer.

Another inverter adjusts the spindle speed, in order to get the ideal cutting speed at all times and according to the different cutting systems, like abrasive sectors for the grinding of cast iron or aluminium cylinder heads with pre-chambers, the tool for aluminium resurfacing or the CBN-PCD toolholder plate for high-speed resurfacing.

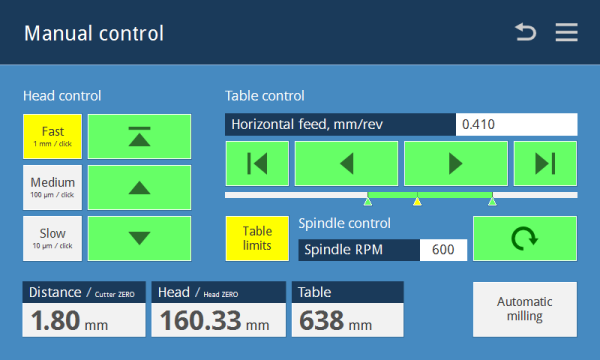

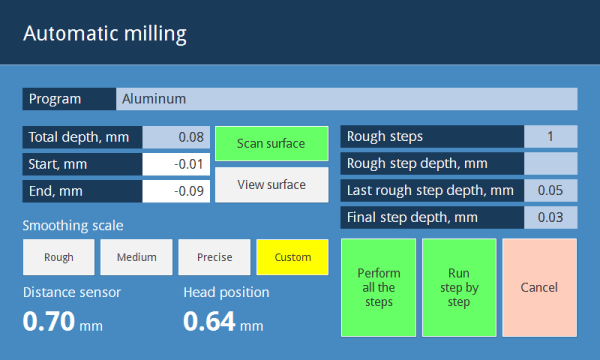

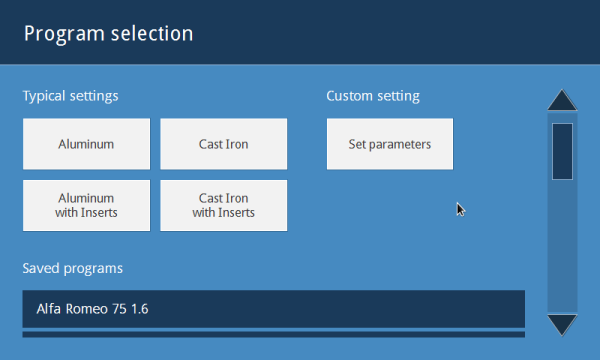

This machine is CNC controlled

For an easy and safe use of the machine, all information and control commands are located on a rotating control panel with touch screen that can be adjusted to every operator. Moreover, in order to supply an efficient product, the machine’s standard equipment includes the rapid movement of the head, an efficient cooling system complete with a settling tank, and a wheel dressing assembly with diamond dresser.

Useful accessories are also available upon request, such as the adjustable set-up fixture for cylinder heads, the V-block mounting kit, the rotating backing pad for the grinding of flywheels, clutch friction plates or brake discs.

Comec RP1000CNC resurfacer specifications

| Table travel | 1070 mm |

| Max working length | 895 mm |

| Max working width | 355 mm |

| Min - Max working height | 920x210 mm |

| Useful table surface | 358 mm |

| Milling plate diameter | 0÷1500 mm/min |

| Spindle rotation speed | 2,2 kW |

| Variable table feed speed | 0.75 kW |

| Spindle motor | 1.27 Nm |

| Table motor | 1680x1140x1850 mm |

| Feed torque motor | 1015 Kg |

Standard equipment

- Ball screw drive feed of table and head complete of speed adjuster

- Ø 358 mm milling plate with CBN insert

- Touch screen CNC control panel

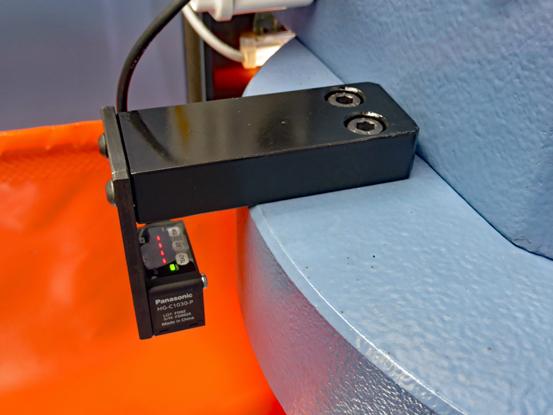

- Laser sensor for scanning workpiece

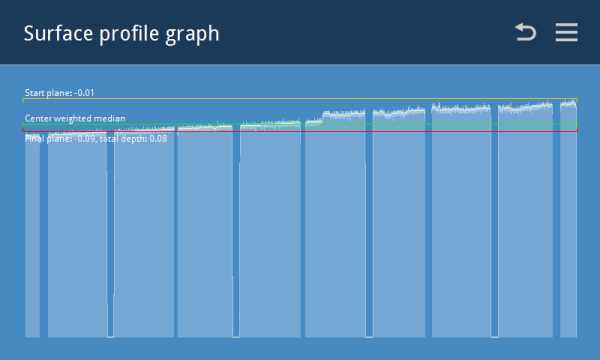

- Surface profile graph

- Fully automatic cycle

- Database with preloaded working cycles and possibility to personalize them

- Estimated cycle time

- Safety guard with sliding doors

- Pair of parallel supports

- Large clamps (2 pcs.)

- Small clamps (4 pcs.)

- Oil for slides

- Wrench set

- Instruction manual

Accessories and spare parts

Our machines

Contact us

FijnTechniek Fijnaart BV

Blaaksedijk 30A

4793RN Fijnaart

The Netherlands

+31 168 46 44 61